Many methods of food preservation are effective, but few are as long-established as fermentation. The natural process, in which microbial enzymes act on and convert a substrate, has been used for millennia, dating back to ancient Mesopotamia and the making of bread and beer.

Today, fermentation is still a method of choice for many food and beverage manufacturers, including meat and poultry processors. The original reasons for using this technique – to preserve food and enhance flavor – still drive the use of fermentation, along with other benefits relevant to today’s marketplace, from simpler ingredients to natural health benefits to more sustainable solutions.

In addition to such items as cultured dairy products, beers/ciders, kimchi, sauerkraut and coffee, many types of meat and poultry products can be fermented or produced through the fermentation process. Within the meat and poultry category, applications include traditional fermented products like sausage and salami and ready-to-eat (RTE) proteins.

“There are specific microbiologic challenges in meat that make fermentation an important tool,” explains Amber Beckett, product manager for Corbion, the country’s largest and most experienced producer of antimicrobial ingredients.

Such challenges include harmful pathogens that grow in meat, such as Listeria monocytogenes, E. coli and Salmonella. Those and other pathogens are responsible for tens of thousands of cases of foodborne illness each year in the U.S. and can be linked to costly, brand-damaging product recalls.

Beyond steps like cooking and refrigeration that eliminate pathogen (cooking) or keep them at bay (freezing), fermentation kills hazardous microbes. “Microbes need free water to grow, so if that is limited by adding a ferment, you can reduce that food safety hurdle. Another hurdle is pH, and acidified meats make it more difficult for microbes to flourish,” says Beckett.

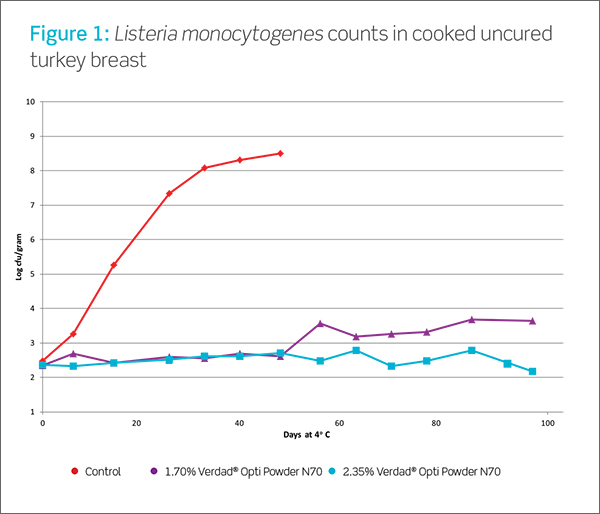

Corbion’s fermentation solutions include a line of Verdad® ferments that control the growth of pathogens. In cured meats, for instance, the solutions have been shown to inhibit the growth of Listeria from 90 to 120 days.

In addition to reducing the risk of harmful pathogens, fermentation extends the shelf life of meat and poultry products. Some fermented meats have a shelf stable life of up to 40 days.

Ferments are also used to impart unique flavors in meat and poultry products. One example is Corbion’s PuraQ® Arome NA4, which improves the overall flavor profile of meat by increasing savory notes, according to Beckett.

Color stability is a benefit as well, given the fact that many consumers shop with their eyes when browsing the meat case.

Beyond functionality, meat and poultry companies are turning to ferments to meet growing consumer demand for recognizable ingredients. Verdad® ferment blends are made with “kitchen cupboard” ingredients such as cane sugar, corn sugar or other substrates.

Today’s ferments are versatile enough for a broad range of applications, including RTE meat and poultry products with different pH ranges and with varying level of fat and proteins. “The Verdad® ferment blends are also non-toxic and stable with different food processing technologies,” adds Beckett.

As people have changed the way they shop and consume food in the wake of the global pandemic, the need for flavorful, safe foods with a longer shelf life remains strong. Whether they are preparing meals at home using foods from their stocked pantries and refrigerators or excitedly dining away from home after a year largely away from in-person eating in restaurants, consumers have high expectations for quality and safety and are increasingly seeking out products with a natural profile.

To learn more about Corbion’s ferments, visit Corbion.com/verdadferments.

|

Verdad® Ferments Naturally derived solutions for ready-to-eat meats and poultry products, with food safety and shelf life benefits:

|